is part of the Informa Markets Division of Informa PLC

This site is operated by a business or businesses owned by Informa PLC and all copyright resides with them. Informa PLC's registered office is 5 Howick Place, London SW1P 1WG. Registered in England and Wales. Number 8860726. Welding Polyethylene Sheet

There are thousands of plastics on the market that can be used for rapid prototyping or low-volume manufacturing—choosing the right one for a given project can be overwhelming, especially for first-time inventors or new entrepreneurs. Each material has trade-offs when it comes to cost, strength, flexibility and surface finish. Consideration must be given not only to the application of the part or product, but also to the environment in which it will be used.

Overall, engineering plastics have advanced mechanical properties that offer greater durability and that won’t be compromised during the manufacturing process. Modifications also can be made to some types of plastics to improve their strength as well as their impact and heat resistance. Let’s delve into the different plastic materials to consider depending on the final part or product’s function.

One of the most common resins used to make mechanical parts is nylon, aka polyamide (PA). When PA is mixed with molybdenum it has a slippery surface for easy motion. However, using nylon-to-nylon gear trains is not recommended, as similar plastics tend to stick together. PA is highly resistant to wear and abrasion and has good mechanical properties at elevated temperatures. Nylon is ideal as a filament for 3D plastic printing, but it absorbs water over time.

Polyoxymethylene (POM) is also a great option for mechanical parts. POM is a type of acetal resin, used to make Dupont’s Delrin, a valuable plastic for gears, screws, wheels and more. POM has high flexural and tensile strength, stiffness and hardness. However, POM can degrade with alkali, chlorine and hot water and can be difficult to bond together.

If your project is a vessel of sorts, polypropylene (PP) is best. PP is used for food-storage containers because it is heat resistant, is impervious to oils and solvents and doesn’t leach chemicals, making it food safe. PP also has a superior balance of stiffness and impact strength and can be easily formed into a hinge that can be bent repeatedly without breaking. It can also be used for applications in pipes and hoses.

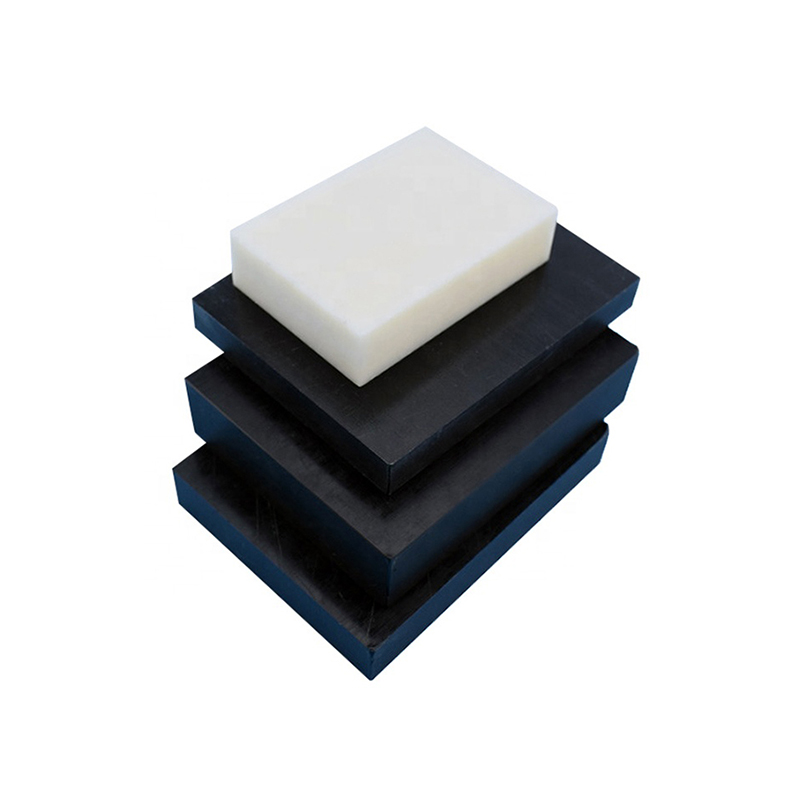

Another option is polyethylene (PE). The most common plastic in the world, PE has low strength, hardness and rigidity. It usually has a milky white color and is the plastic found in medicine bottles and milk and detergent containers. PE is highly resistant to various chemicals, but has a low melting point.

For any project needing high impact resistance and strong resilience to tearing and breaking, acrylonitrile butadiene styrene (ABS) is ideal. ABS is lightweight and can be strengthened by adding glass fibers. It is more expensive than styrene, but lasts much longer due to its hardness and toughness. ABS is used for 3D fused deposition modeling of rapid prototypes.

Given its properties, ABS is a good option for wearable devices. At Star Rapid, we created a smart watch case for E3design with black, pre-colored ABS/PC plastic resin using plastic injection molding. This material choice allows the overall device to stay relatively light, while also providing a shell that can endure accidental impacts, such as when the watch hits a hard surface. If you need something that is versatile and impact resistant, high-impact polystyrene (HIPS) is a good option. This material is suitable for creating tough cases for power tools and tool boxes. While HIPS is economical, it is not considered environmentally friendly.

Many projects call for injection molding of resins that have the soft, elastic properties of rubber. Thermoplastic polyurethane (TPU) is a great option, as it comes in many special formulas to achieve high elasticity, low-temperature performance and durability. TPU is also used in power tools, caster wheels, cable insulation and sporting goods. As it is solvent resistant, TPU can be found in many industrial environments due to its high abrasion resistance and shear strength. However, it is notorious for absorbing moisture from the atmosphere, so it can be difficult to process during manufacturing. For over-molding, there’s thermoplastic rubber (TPR), which is inexpensive and easy to handle for applications like cushioned rubber grips.

If your part requires clear lenses or windows, acrylic (PMMA) is best. This material is used to make shatterproof windows like Plexiglass because of its rigidity and abrasion resistance. PMMA also takes a high polish, has good tensile strength and is economical in large volumes. However, it is not as impact or chemical resistant as polycarbonate (PC).

If you need something stronger for your project, PC is more durable than PMMA and has excellent optical properties, making it an appropriate choice for lenses and bulletproof windows. PC also can be bent and formed at room temperature without shattering. It’s useful for prototyping work, since it does not require expensive mold tools to shape. PC is more expensive than acrylic and may release harmful chemicals when exposed to hot water for extended periods of time, so it’s not food safe. Due to its impact strength and resistance to scratches, PC is ideal for a variety of applications. At Star Rapid, we used this material to create covers for handheld point-of-sale terminals for Muller Commercial Solutions. The part was CNC machined from solid blocks of PC; since it needed to be completely transparent, it was then hand sanded and vapor polished.

This is just a quick look at some of the most commonly used plastics for manufacturing. Most can be altered with various glass fibers, UV stabilizers, lubricants or other resins to achieve specific engineering properties based on the needs of the project and the manufacturing process being used—whether it’s injection molding, vacuum casting or 3D printing.

Gordon Styles is the founder and president of Star Rapid, a provider of rapid prototyping, rapid tooling and low-volume production services. Utilizing his background in engineering, Styles founded Star Rapid in 2005 and under his leadership the company has expanded to 250 employees. With an international team of engineers and technicians, Star Rapid combines advanced technologies—such as 3D printing and multi-axis CNC machining—with traditional manufacturing techniques and high-quality standards. Prior to Star Rapid, Styles owned and managed the United Kingdom’s largest rapid prototyping and rapid tooling company, STYLES RPD, which was sold to ARRK Europe in 2000.

More information about text formats

Extruded Nylon Rod Stay on the bleeding edge of plastics innovation with PlasticsToday's coverage of the latest advances in materials.